The Turnado Freehand Metal Turning System

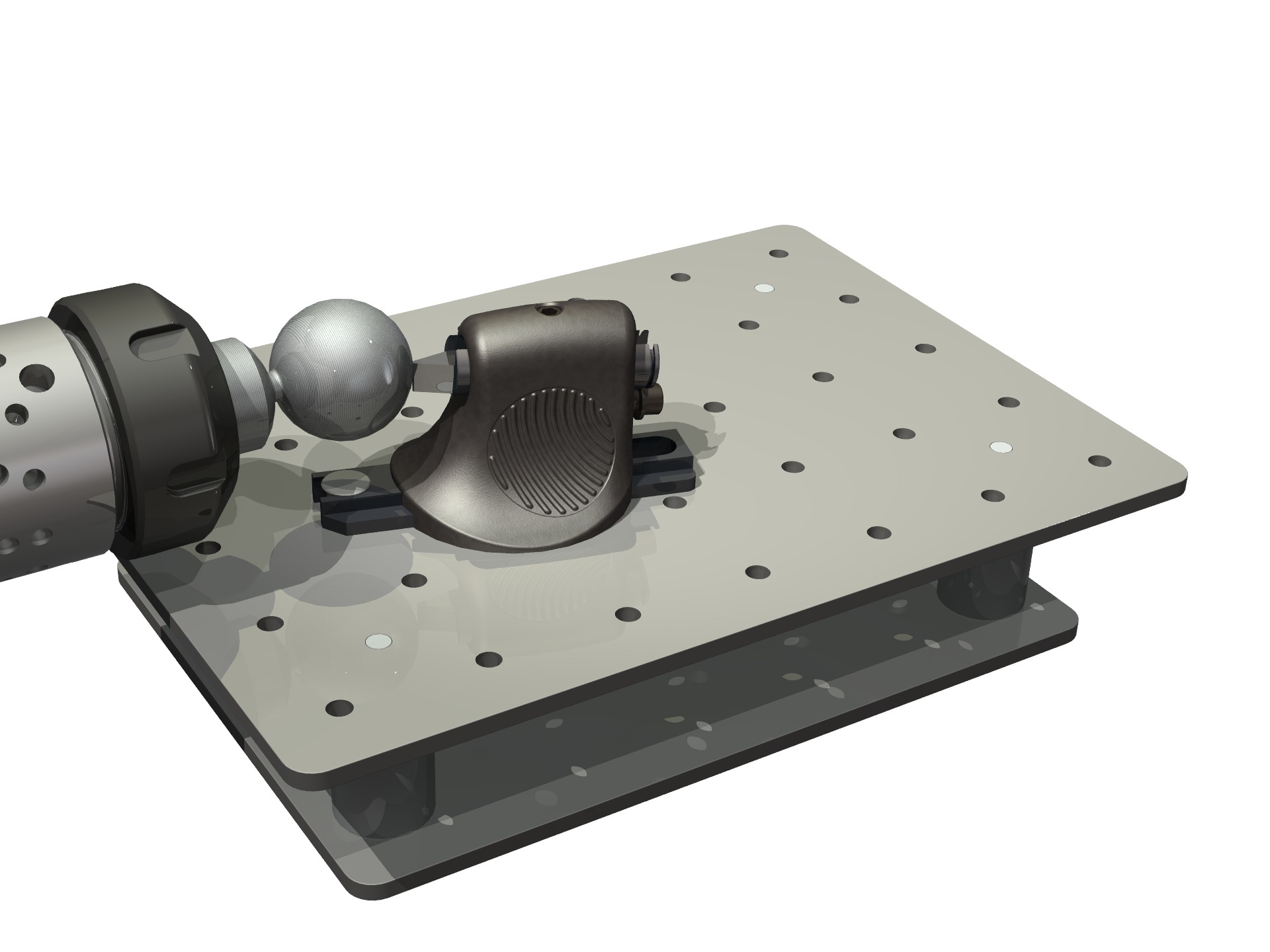

Basic Turnado System including the General Purpose Radius Shoe.

Produce items you never thought possible with a standard metal working lathe.

- Turn large and small internal and external radii at any position on the workpiece.

- External and internal hemispheres as well as complete sheres from 2mm to 50mm diameter.

- Produce Toroids (donuts) Ovoids (egg shapes) and Ellipsoids.

- Create freehand curves to whatever shape you like.

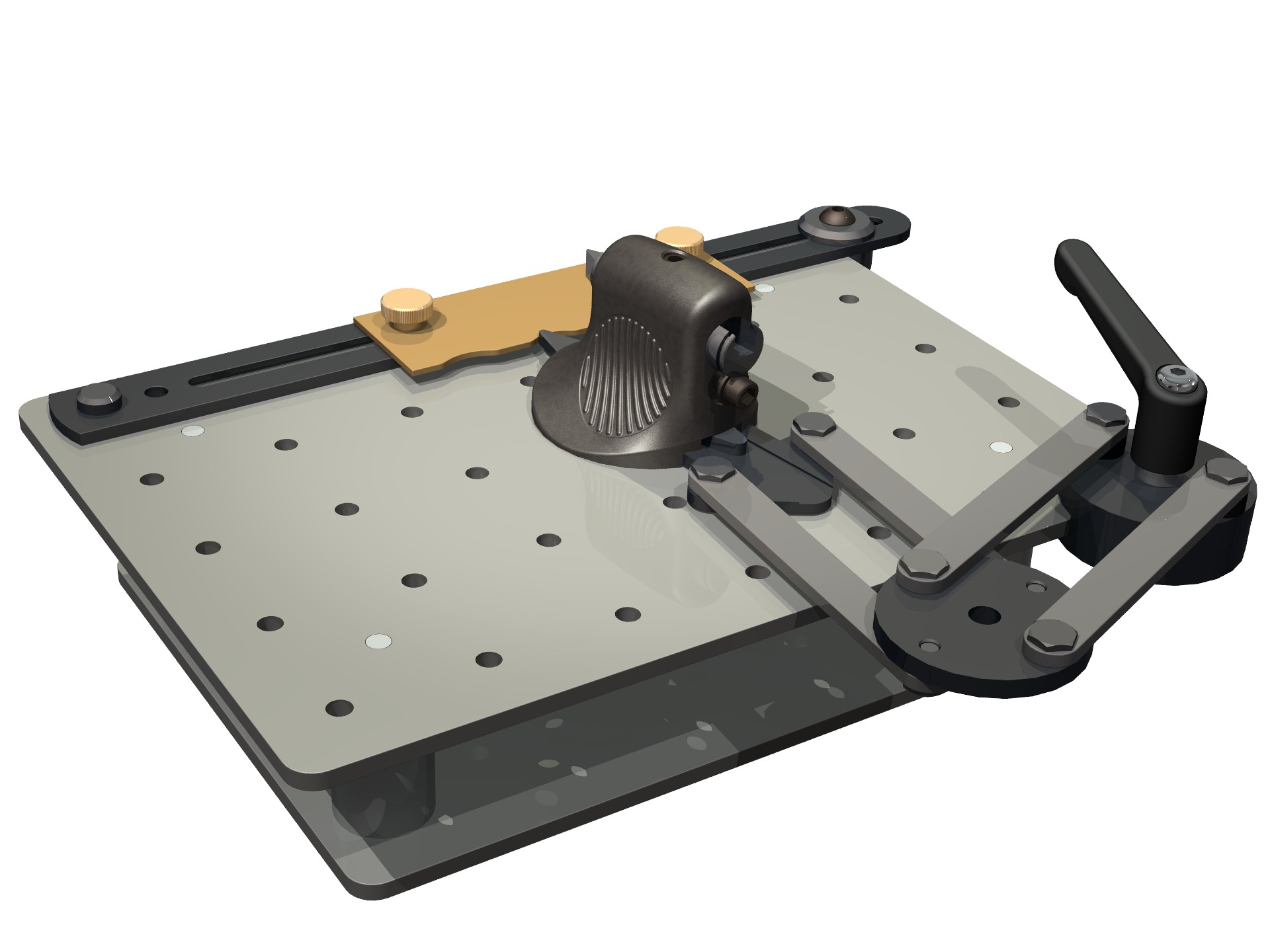

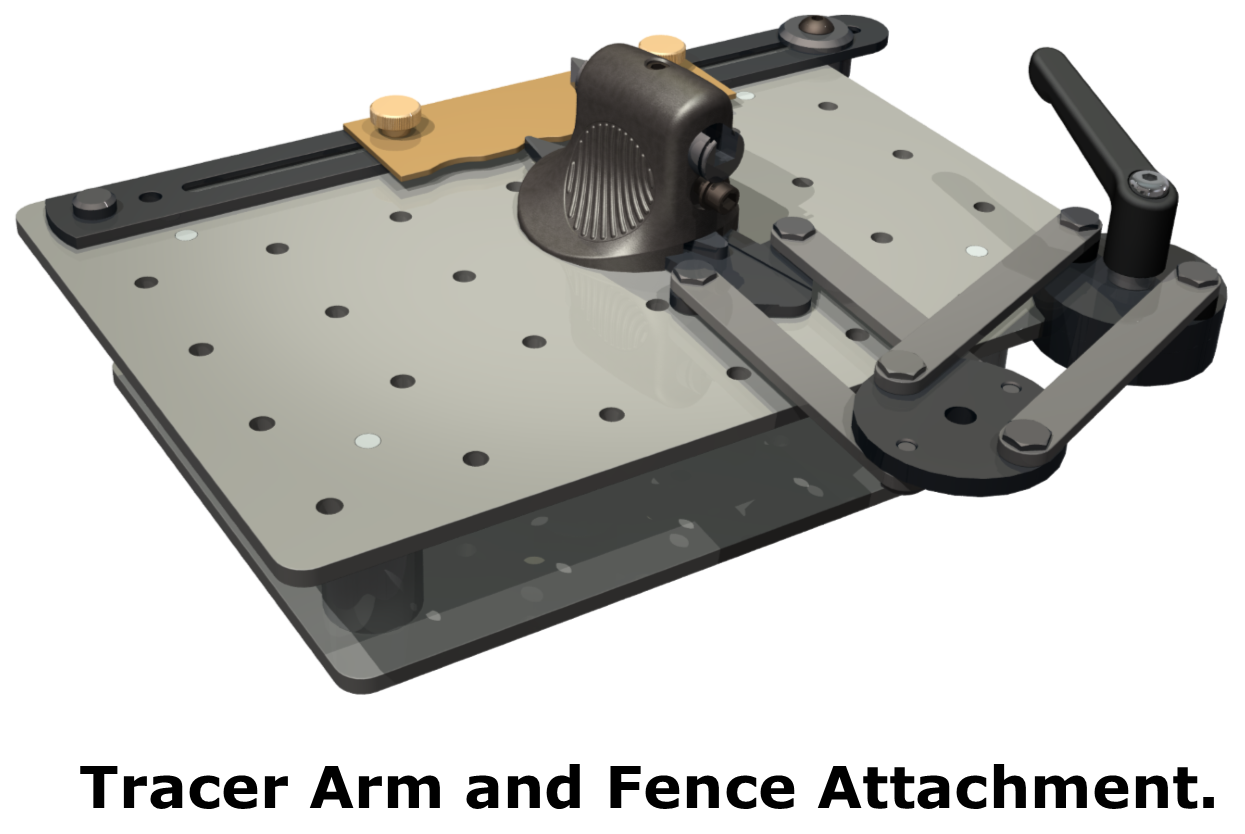

- Reproduce multiple identical shapes such as chess pieces, canons for model ships and miniature candlesticks etc using the tracer arm and a simple sheet metal template.

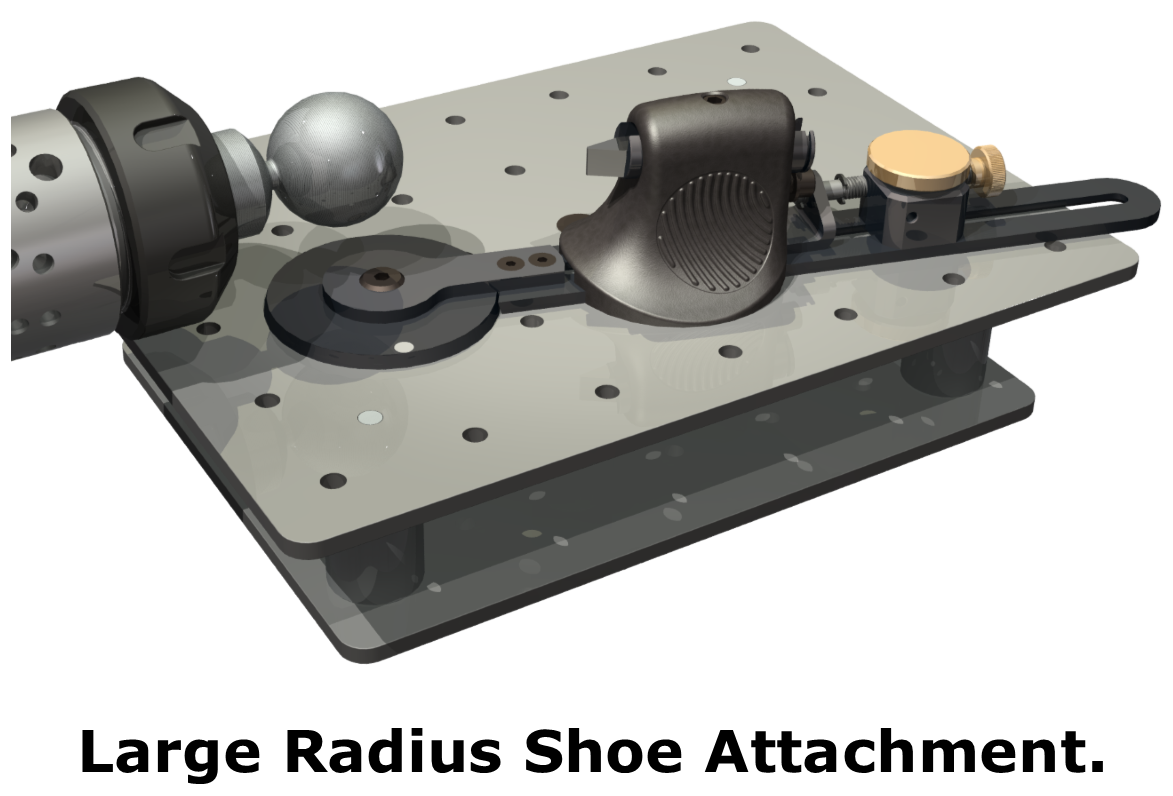

- Large radii up to 150mm (6") can be turned using the Large Radius Shoe, or huge radii as big as you like using a curved template with the Tracer Arm.

- Large and small taper turning using the Tracer Fence set at an angle

- Adaptable to fit on the cross slide of virtually any small to medium sized lathes, and quick to swap over in place of the top slide.

- _______________________

Ideal for jewellery making, ornamental turning, model making, clockmaking and many other types of decorative and curvilinear work.

So much more than just a ball turner!

The Turnado System has been designed to allow the user to easily

turn internal and external curves and radii on most bench top lathes.

This can be accomplished in several ways.

____________________

Sliding the toolpost around on the worktable to form curves and shapes

completely freehand.

Using the General Purpose Shoe and pivoting off a stop pin placed

in one of the grid holes.

Using the Large Radius Shoe accessory, this has an adjustable eccentric

pivot so that full spheres can be turned without re-chucking.

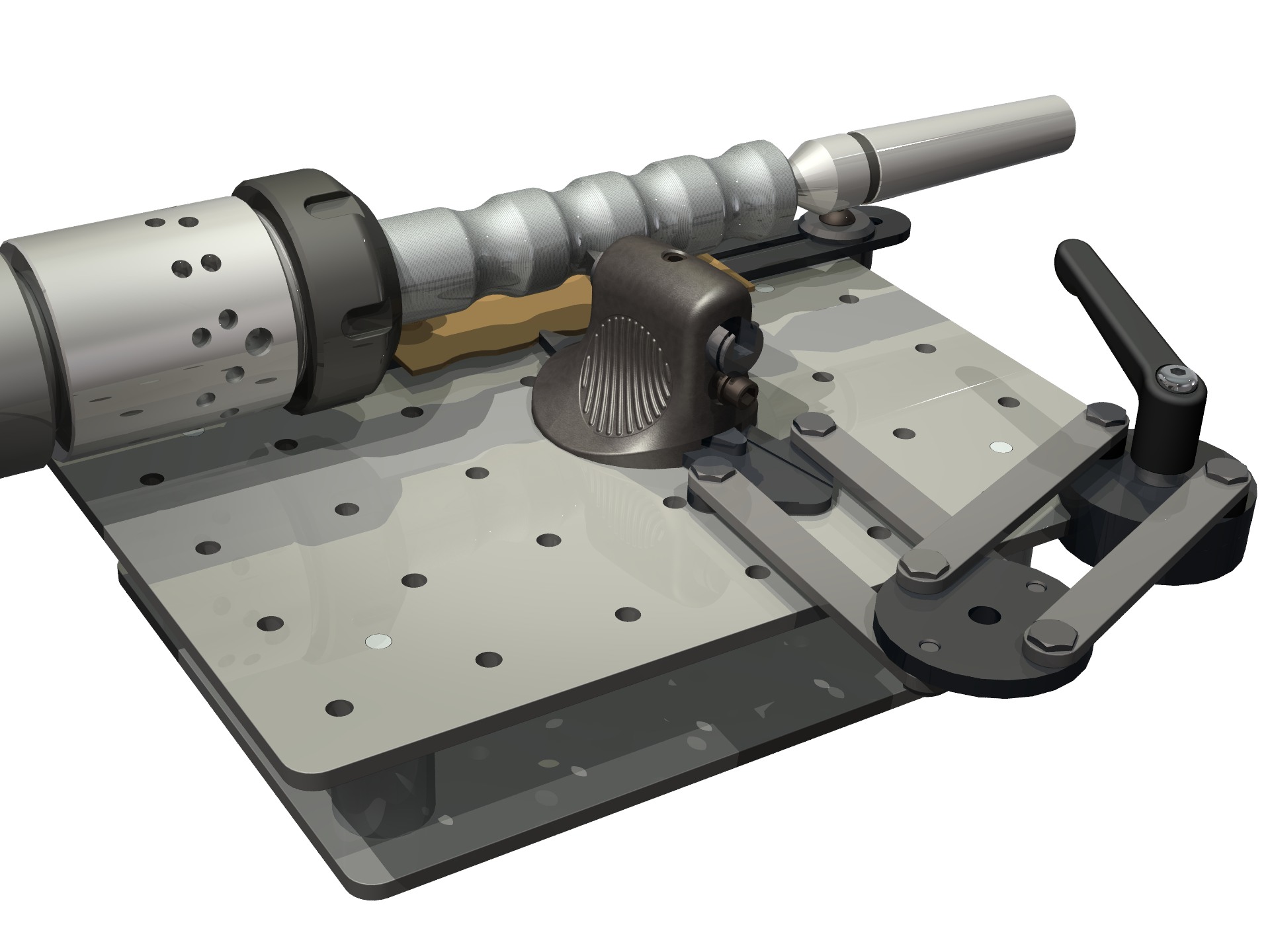

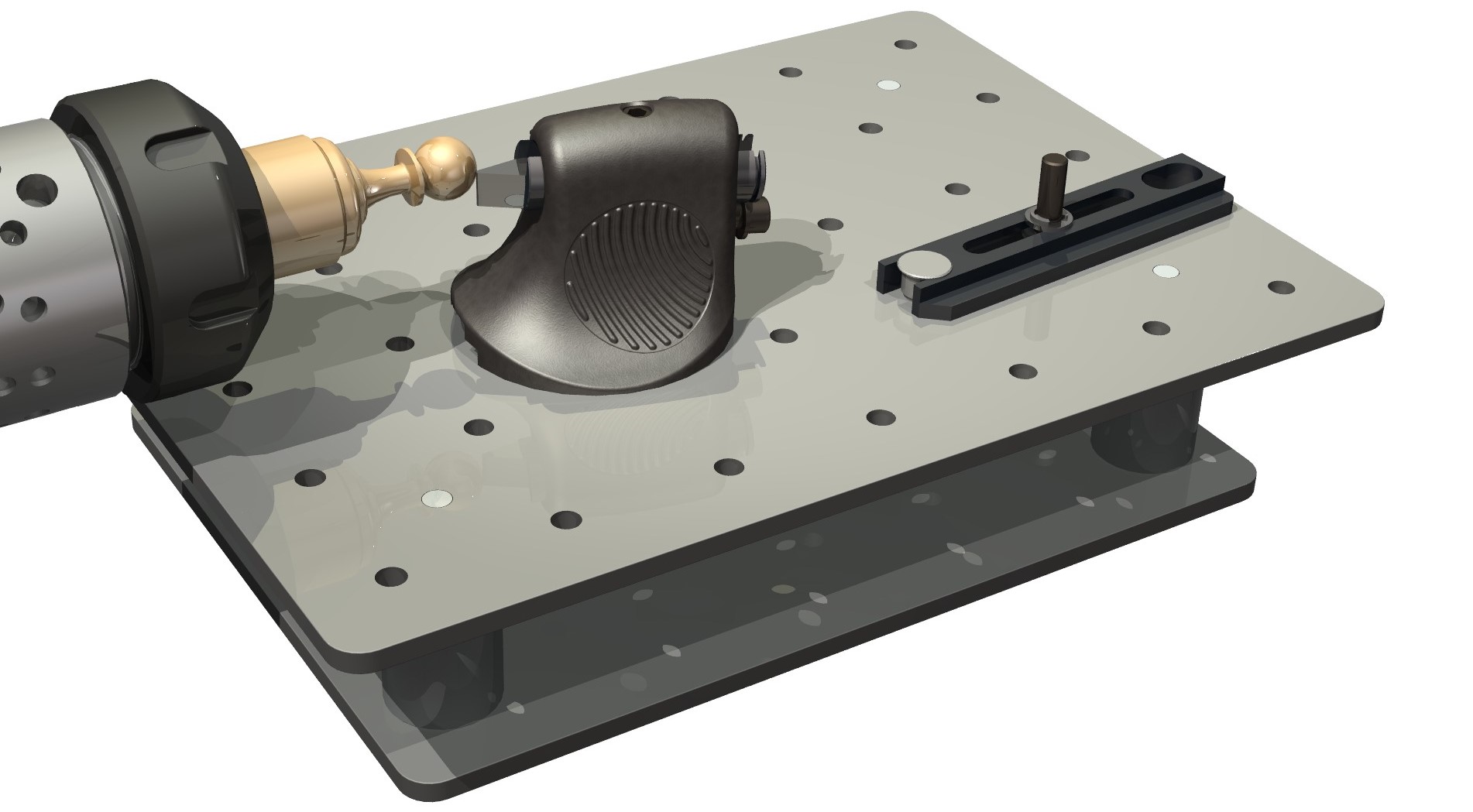

Using the Tracer Arm accessory with a shaped template. With this

method, huge radii not possible with a pivot system can be created.

The basic system consists of a 150mm x 210mm(6"x8") steel worktable with

a grid pattern of holes.

This is supported on five aluminium pillars which are turned to length by you

to match the centre height of your lathe.

The five pillars are attached to a bottom adapter plate that is modified to fit

the mounting configuration of the top slide on your lathe.

When in use the worktable is easily mounted to the cross slide in place of

the top slide, on some lathes this is just a matter of loosening two set screws.

The toolpost block is made from investment cast Ductile Cast Iron which helps

it slide around on the worktop easily.

The block has a slotted insert with a built in fine adjustment that gives

0.5mm(0.020") vertical height adjustment to allow for cutter differences

and resharpening.

The toolpost insert takes 1/4" square HSS tool bits and inserts for 6mm tool

bits are also available.

A "T" slot and two tapped holes are machined into the base of the tool post so

that it can be mounted to various accessory "Shoes"

A zero rake angle on the top of the cutter combined with a small front clearance

angle ensure the tool bit and tool post block will not be pulled into the workpiece.

So long as the tool bit is not extended out beyond the area of the base the

Toolpost cannot be tipped over, no matter how much downward pressure is applied.

Some smaller examples of what can be achieved with the

Turnado System.

The materials used in the items above include.

Brass (C38500*)

Clear Acrylic Rod

Bright Mild Steel (S1214*)

Ductile Cast Iron

Aluminium (2011*)

Stainless Steel (303*)

* Free machining grades